As the title suggests, the relief load is calculated based on the expansion of the fluid due to absorbed heat.

“Rigorously Size Relief Valves for Supercritical Fluids”2.“A Calculation of Relieving Requirements in the Critical Region”1.In the absence of a better method, this led to the use of 50 Btu/lb for even supercritical fluids. API 521 suggests the use of a latent heat of 50 Btu/lb for hydrocarbons near the critical point.The following sources include some of these methods: N the past 40 years, several different methods have been suggested for relief load and pressure relief valve (PRV) orifice sizing calculations for a supercritical fluid exposed to an external heat source. This is where this article differs from the one presented at the API meeting.3 (Smaller temperature increments result in a smaller enthalpy change, Δh, which translates to a smaller time span.) In fact, it is possible to mathematically prove that the two peaks occur at two different temperatures for real gas. Improving the calculation precision by reducing the temperature increments does not affect the temperatures at which the mass and the volume relief rates peak. Both temperatures where the maximum relief rates occur are greater than the critical temperature. The results indicate that the maximum mass relief rate occurs at lower temperature than the maximum volumetric relief.

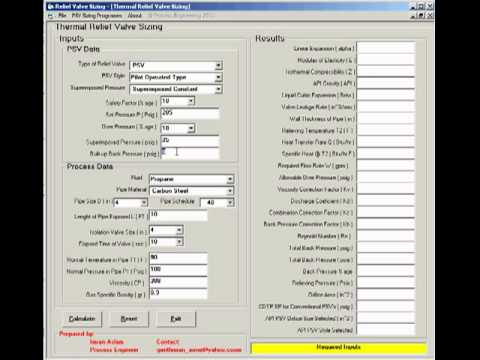

PSV SIZING SERIES

In this study, a series of calculations were conducted for randomly selected n-paraffins, i-paraffins and aromatic compounds from C1 to C16, using the Peng-Robinson equation of state (EOS). The volumetric and mass relief rates for each interval can be calculated using Eq.

PSV SIZING SIMULATOR

To estimate the relief rates at different intervals, one can generate a property table in a process simulator to calculate the densities and specific enthalpies of the fluid at a constant relief pressure over a given temperature range. ⎛ ρ + ρ2 ⎞⎟ M R = ⎜⎜⎜ 1 ⎟×V (2) ⎝ 2 ⎟⎠ R where: MR = Mass relief rateīoth the volumetric and mass relief rates will change during the course of a relief as the specific volume and enthalpy of the fluid change. Where: VR = Volumetric relief rate Q = Heat input h1 = Initial specific enthalpy h2 = Final specific enthalpy ! = Initial density ' = Final density The mass relief rate can be determined using the average of the initial and final densities for each interval. Mass method 1 Mass method 2 Volume method 1 Volume method 2 PRICE, Jacobs Consultancy, Houston, Texas NEZAMI, Jacobs Engineering, Houston, Texas and J. Fine-tune relief calculations for supercritical fluids Improved process simulation assists with relief load and valve sizing P.

0 kommentar(er)

0 kommentar(er)